Ó 2007 Predictive Maintenance Technologies LLC

Newberg, OR

Vibration Analysis

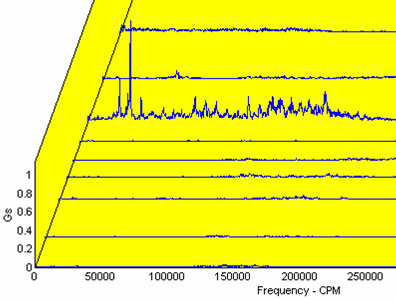

Vibration analysis is a non-invasive method to monitor rotating equipment to find problems such as bearing defects, mechanical looseness, out-of-balance conditions and misalignments.

Vibration analysis helps keep production running smoothly by reducing unscheduled downtime, lowering maintenance costs, prolonging machinery life, and increasing safety.

Using portable vibration sensing equipment, a technician periodically monitors equipment looking for deviations from baseline vibration levels. The technician then reports the level, making recommendations about when repairs or replacements should be done -before an unplanned and costly failure occurs.

Setting up a regular schedule

to monitor your critical equipment is recommended.

This allows us to set up a database of your equipment and become familiar with its allowable vibration levels. We will then be better able to serve you by recording problems at an early stage - allowing you time to repair a problem before a breakdown occurs.

Read more about the

97% of sawmills rate

vibration analysis

as the

most valuable service

in the predictive maintenance field.

-Solutions Magazine August 2002